Assembly Services

Unleash the Power of Seamless PCBA Processing with [KEEP BEST]

In the intricate landscape of electronics manufacturing, [KEEP BEST] emerges as the ultimate partner for all your Printed Circuit Board Assembly (PCBA) needs. With our dual manufacturing bases in China and Thailand, state-of-the-art production lines, and a team of dedicated professionals, we are committed to delivering top-tier PCBA solutions that exceed your expectations.

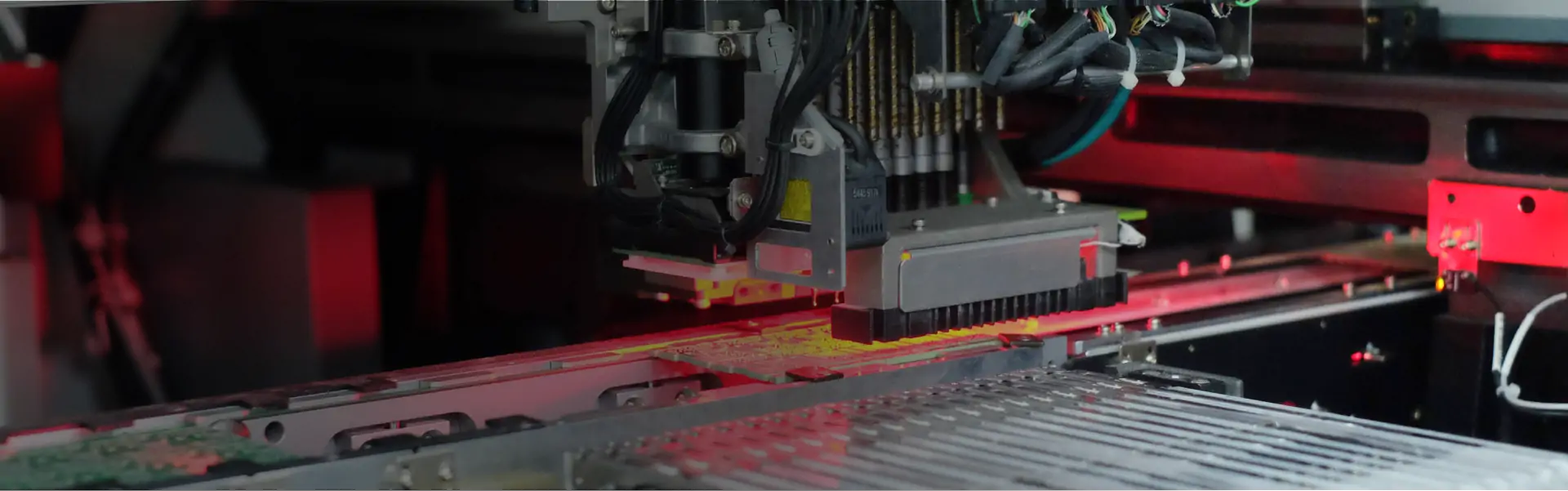

Unparalleled Manufacturing Infrastructure

Our robust manufacturing setup is the cornerstone of our exceptional PCBA services. Boasting 16 advanced Surface Mount Technology (SMT) automated production lines and 8 through-hole Dip-Insertion (DIP) lines, we have the capacity to handle projects of all scales, from small-batch prototypes to large-volume mass production. The SMT lines are equipped with high-speed pick-and-place machines, precision solder paste printers, and advanced reflow ovens, ensuring accurate component placement and reliable soldering with tight tolerances. Our DIP lines, on the other hand, are optimized for the assembly of through-hole components, providing seamless integration of various electronic parts.

Located strategically in China and Thailand, our two production bases offer distinct advantages. The China base, with its established supply chain and expertise in high-volume production, ensures efficient manufacturing and cost-effectiveness. Meanwhile, our Thailand base provides proximity to Southeast Asian markets, enabling faster delivery and better support for clients in the region. Together, these bases form a powerful network that allows us to streamline production, reduce lead times, and maintain consistent quality across all our PCBA offerings.

A Team of Seasoned Professionals

Behind our cutting-edge manufacturing facilities is a team of over 450 skilled employees, each bringing a wealth of knowledge and experience to the table. Our engineers, technicians, and production staff are well-versed in the latest PCBA technologies and industry standards. They undergo regular training to stay updated with emerging trends, ensuring that we can handle even the most complex PCBA projects with ease. From initial design review to final product testing, our team works closely together to ensure every step of the PCBA process is executed flawlessly.

One-Stop PCBA Solution

At [KEEP BEST], we understand the value of your time and resources. That’s why we offer a comprehensive one-stop PCBA processing service. All you need to do is provide us with your Bill of Materials (BOM) and PCB design files, and we’ll take care of the rest. Our service encompasses every aspect of the PCBA process, including component sourcing, SMT and DIP assembly, quality control, functional testing, and final packaging.

We have established strong partnerships with a global network of reliable component suppliers, ensuring access to high-quality components at competitive prices. Our procurement team meticulously verifies each component to ensure it meets our stringent quality standards. During the assembly process, our advanced production lines and skilled operators guarantee precise component placement and soldering. Rigorous quality control measures, including automated optical inspection (AOI), X-ray inspection, and in-circuit testing (ICT), are implemented at multiple stages to detect and rectify any potential defects, ensuring that the final PCBA products are of the highest quality and reliability.

Benefits of Choosing [KEEP BEST]

• Quality Assurance: Our adherence to international quality standards, combined with our advanced inspection and testing processes, ensures that every PCBA we produce meets or exceeds your quality requirements.

• Cost-Efficiency: Leveraging our large-scale production capabilities, optimized supply chain, and dual manufacturing bases, we offer competitive pricing without compromising on quality.

• Fast Turnaround: With our efficient production processes and strategic location of production bases, we can provide quick delivery times, helping you get your products to market faster.

• Technical Expertise: Our experienced team is always ready to provide technical support, offering solutions to complex design and manufacturing challenges.

Partner with [KEEP BEST] Today

Whether you’re a startup looking to bring your innovative product to life or an established enterprise in need of reliable PCBA services, [KEEP BEST] is your trusted partner. Contact us today to discuss your PCBA project requirements, and let us show you how our one-stop PCBA processing service can transform your ideas into high-quality, market-ready products.

Is there a minimum order quantity (MOQ) for product orders?

No, we adopt a flexible order mechanism, there is no MOQ for products; The number of orders is entirely up to you.Thank you for choosing KeepBest.

What is your testing policy and how you control the quality?

ln order to guarantee PCB product quality,usually tested by flying probe; electrical fixture; automated optical inspection (AOI); X-ray inspection for BGA parts; first article inspection (FAl), and so on.

What service do you have?

We can offer OEM service including PCBA making, PCB assembly, components sourcing. Additionally, we can also provide programming, testing, cables, enclosure assembly service.

Do you support quick proofing?

Yes,we support 3-7 days fast proofing.

Are my files safe?

Your files are held in complete safety and security. We protect the intellectual property for our customers in the whole process. All documents from customers are never shared with any third parties. NDA can be signed.

If we have order production needs, how can we contact you?

Thank you very much for your trust in our company. If you have any questions, please feel free to email our sales team at mailto:market@keepbestpcba.com. We are available 24/7 to serve you.