One-Stop PCBA Manufacturer with

14 SMT Lines

ISO13485 / IATF16949 Certified | EMS & OEM | Quick-turn PCBA from China & Thailand

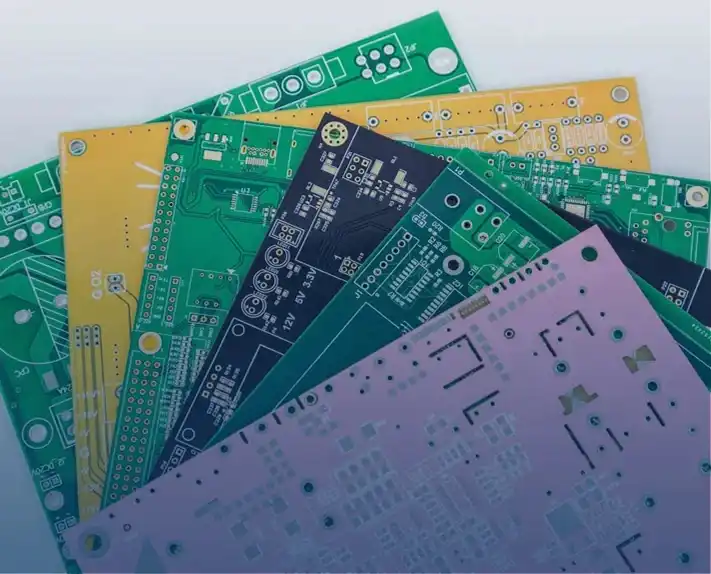

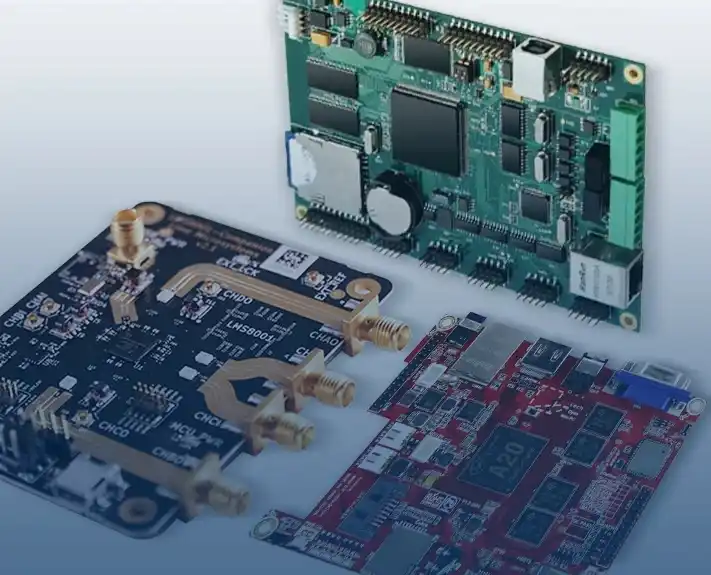

Keep BestPCBA is a one-stop EMS solution service provider who integrates PCB Layout, PCB manufacturing, PCBA solution and product design, component procurement, SMT, DIP, finished product assembly and testing, having over 13 years of experience in serving many domestic and foreign brand customers in a wide range of fields such as Medical.We have a 50-person R&D engineer team and a workforce of 600 employees, with production bases in Thailand, Shenzhen (China), and Jiangmen (China), totaling over 6,0000 square meters of manufacturing space.

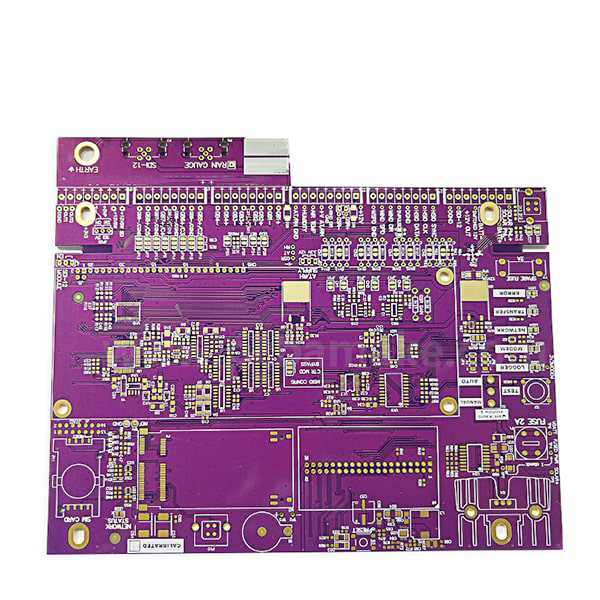

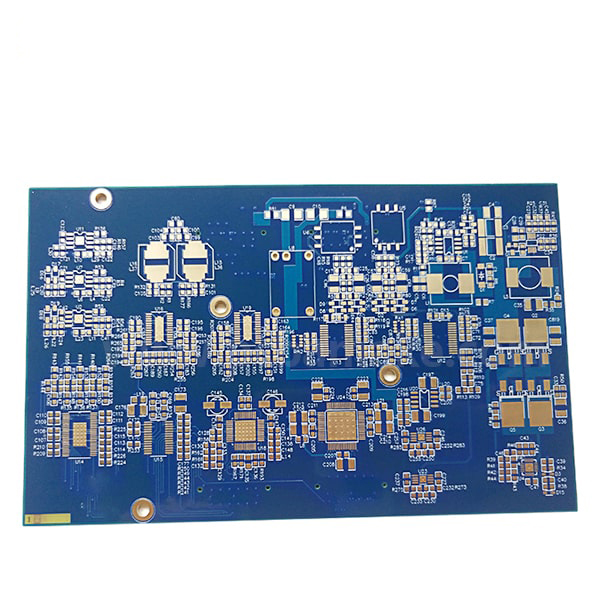

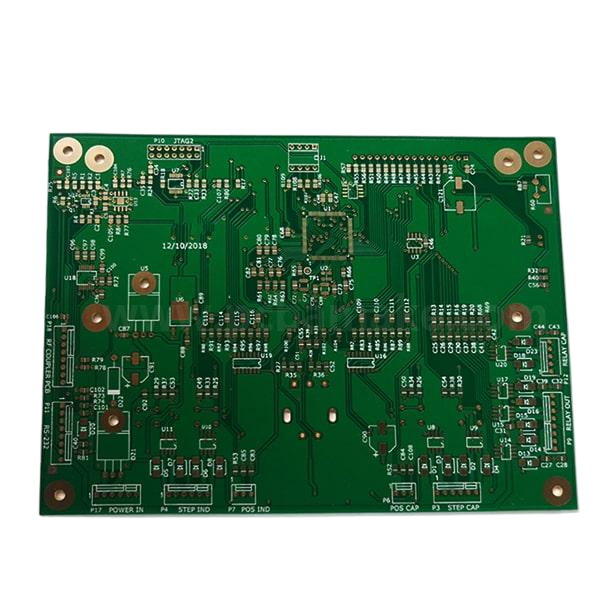

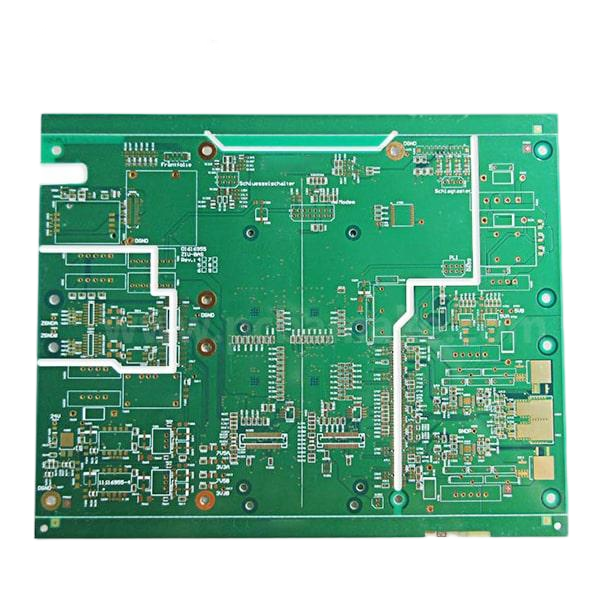

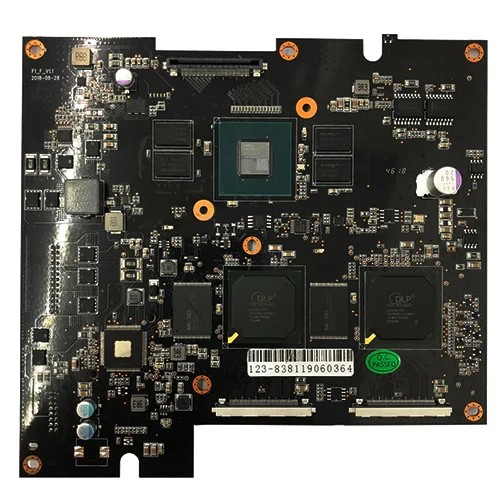

Specialized in high-precision manufacturing (≤50μm line width, 0.25mm micro-pitch welding), complex processes (mixed assembly/underfill/20+ layer boards). Certified to IATF 16949/ISO 13485, with Cpk≥1.33 for critical processes. Full traceability via MES + 8D reports. Equipped with X-Ray/3D AOI and ≥95% ICT/FCT testing; provides ORT reliability reports.

Fast turnaround: ≤7-day prototypes, ≤20-day small batches; 72-hour emergency prototyping. Integrated with Digi-Key/Mouser, offering Second Source solutions, VMI, and 600+ long-lead components (Lead Time>26 weeks). Full compliance: CE/FCC/RoHS, COO, MSDS, ITAR, and ESG standards. DHL delivery within 48 hours globally.

it uses 16 SMT lines for 5-day prototyping and high-volume manufacturing. Services include Valor-based DFM, component sourcing, assembly, system integration, and enclosure/wire harness fabrication. ISO-certified QC with AOI/XRF/FCT ensures quality. Flexible OEM/ODM models, IP protection, branding, and regulatory support via global supply chain accelerate IoT product launch.

Plant area

Countries & Regions

Total number of employees

Full-Cycle PCB Design Expertise

Prototype-to-Mass Production Support

Post-Production Technical Support

Integrated Cost-Efficiency Design.

Automation-Optimized Assembly

Reliability-Driven Manufacturing.

Fast Turnkey PCB Solutions

Prototype-Driven Design Perfection

Flexible Volume Manufacturing

Ultra-Fast Delivery Assurance

Flexible Turnkey Assembly Options

Scalable Craftsmanship Expertise

Cost-Efficient Rapid Sourcing

Reliable Authorized Supply Chains

Customized Procurement Flexibility

Comprehensive Defect Detection

Engineer-Certified Protocols

End-Stage Quality Assurance

We are committed to providing you with zero-defect products.

In the pursuit of quality, we are always worthy of your trust.

No physical objects, no photos, no reason to return or exchange.

RFQ (Request for Quotation).

Technical Review

BOM (Bill of Materials).

Review Cost Estimation

PO (Purchase Order) Confirmation. Contract Signing. Payment Terms. Lead Time Agreement

Gerber File Review Component Sourcing PCB Fabrication Surface Mount Technology

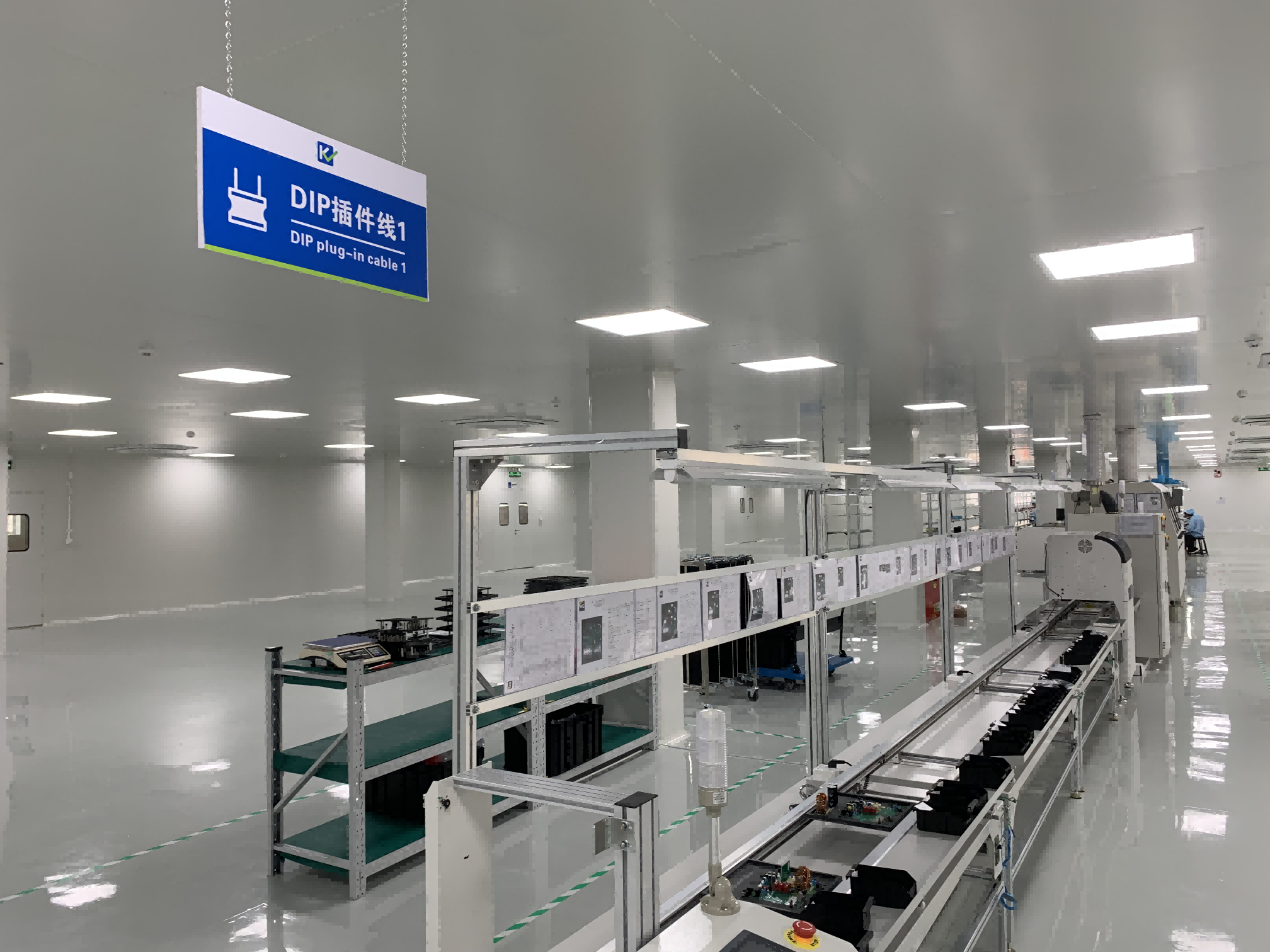

SMT Assembly. DIP (Dual In-line Package) Insertion. Automated Optical Inspection. Functional Testing

Final Inspection. Packaging. Logistics Arrangement. Shipment

We help businesses bring ideas to life in the digital world designing & implementing the technology tools that they need to win. We help business bring ideas to life in the digital wor

The overall project Lead Time is the sum Parts Procurement lead time and PCB Assembly lead time. However, we try to shorten the time line by streamlining our PCB Assembly Process. For instance, once we receive your Gerber Files for PCB Fabrication and BOM for PCB Assembly, we will start to prepare the stencil for your board and complete the fabrication concurrently with the parts procurement process.

No. We have no restrictions on your order size; however, larger orders are more cost effective. If you discuss your target price with your KeepBestPcba account manager, we can work with you to find a good solution for your specific needs in cost reduction.

Bill of Materials, complete information in excel format. This document should include manufacturer names, part numbers, Reference Designators, component descriptions, and quantities. Gerber Files Centroid Data (AKA Pick and Place or XY-Coordinate Data) Other requirements or assembly instructions if applicable

We respect customer's copyright and will never manufacture PCBs for someone else with your design files unless we receive written permission from you, nor we'll share these files with any other 3rd parties. At your request, we can sign an NDA for extra security.

In recent years, the China-US trade war has cast a long shadow over the global trade landscape, and the PCBA (Printed Circuit Board Assembly) industry has not b...