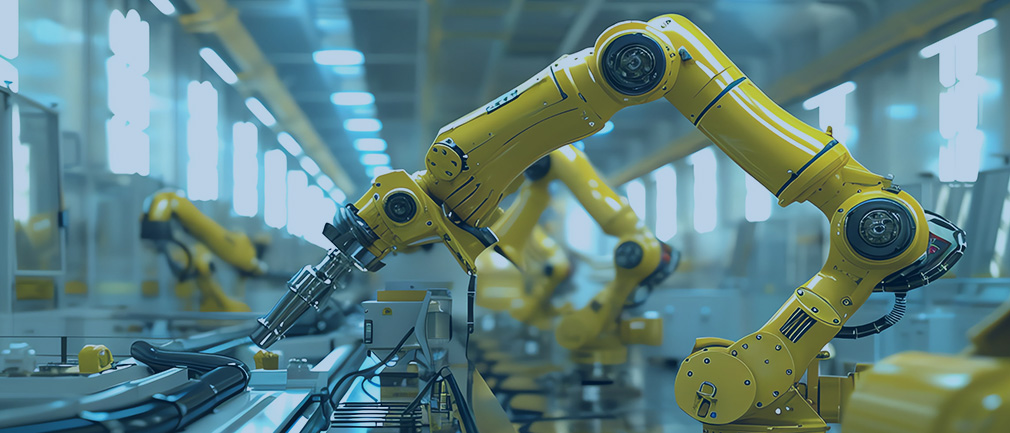

Industrial control

Advanced PCBA Solutions for Industrial Control by [KEEP BEST]

In the highly demanding and complex realm of industrial control, where precision, reliability, and durability are non - negotiable, [KEEP BEST] emerges as a trusted provider of advanced Printed Circuit Board Assembly (PCBA) solutions. Our deep - rooted expertise, state - of - the - art manufacturing capabilities, and unwavering commitment to quality make us the ideal partner for businesses seeking high - performance PCBA for industrial control applications.

Advantages

-

60,000㎡ manufacturing bases in China/Thailand with 16 SMT & 8 DIP lines, equipped with high-speed pick-and-place machines for precise industrial control PCBA assembly.

-

ISO 9001/14001/16949-certified quality control with 100% AOI and X-ray inspection ensures PCBA reliability in harsh industrial environments.

-

Customized solutions for PLCs, HMIs, motor control systems, etc., offering one-stop services from R&D to after-sales support.

ISO - Certified Quality Assurance

[KEEP BEST] (Shenzhen Kingford Technology Co., Ltd.) upholds international quality standards through its comprehensive ISO-certified management systems, ensuring unparalleled reliability in PCBA manufacturing. The company is accredited with:

-

ISO 9001:2015 for its robust Quality Management System, covering end-to-end processes from R&D to after-sales service.

-

ISO 14001:2015 for environmental management, promoting sustainable manufacturing practices.

-

IATF 16949:2016 for automotive industry compliance, meeting stringent requirements for vehicle electronics.

-

ISO 13485:2016 for medical device manufacturing, ensuring safety and regulatory adherence in healthcare applications.

Tailored Solutions for Industrial Control

Programmable Logic Controllers (PLCs)

We specialize in PCBA for Programmable Logic Controllers, the brains of many industrial automation systems. Our PCBA designs for PLCs focus on integrating high - performance microcontrollers, reliable communication interfaces such as Ethernet, RS - 485, and Profibus, and robust power management modules. These components work in harmony to ensure stable operation, accurate data processing, and seamless communication with other devices in the industrial control network. Whether it's for small - scale factory automation or large - scale industrial processes, our PLC PCBA solutions offer the flexibility and reliability needed to optimize production efficiency.

Human - Machine Interface (HMI) Devices

In the development of PCBA for infrared thermal imagers and night vision devices, our experience shines through in every aspect of the design. We've collaborated with major security firms to outfit large - scale industrial complexes, warehouses, and critical infrastructure facilities with surveillance solutions. Understanding the importance of high - sensitivity image sensors, our engineers work closely with clients during the R&D phase to design PCBA layouts that optimize sensor performance. We integrate top - of - the - line image processing chips and carefully select low - noise amplifiers, configuring them to minimize interference, ensuring stable and clear imaging even in low - light or adverse weather conditions. To address heat management, which is crucial for maintaining the performance of temperature - sensitive components during long - term surveillance, we incorporate heat - dissipating materials and strategically place components to ensure continuous operation without degradation.

Motor Control Systems

In motor control systems, where precise speed and torque control are critical, our PCBA solutions play a vital role. We integrate high - performance motor drivers, advanced sensors for feedback control, and intelligent control algorithms (implemented through hardware design rather than software algorithms). Our PCBA designs ensure accurate power regulation, efficient energy consumption, and protection against overloads and short circuits. Whether it's for servo motors in precision manufacturing or large - scale induction motors in industrial machinery, our motor control PCBA solutions can enhance the performance and reliability of the entire system.

Industrial Networking Equipment

With the increasing demand for interconnected industrial control systems, our PCBA for industrial networking equipment, such as industrial routers, switches, and gateways, are designed to meet the highest standards of data transmission and network security. We incorporate high - speed network processors, reliable Ethernet PHY chips, and secure communication protocols. Our PCBA ensure stable and fast data transfer, seamless integration with various industrial fieldbus systems, and protection against cyber threats, enabling efficient monitoring and control of industrial processes across large - scale networks.

Comprehensive Service Offering

Collaborative R&D and Design Support At [KEEP BEST], we understand that industrial control projects often require customized solutions. Our team of experienced engineers offers collaborative R&D and design support from the initial concept stage. We work closely with clients to understand their specific requirements, application scenarios, and performance expectations. Leveraging our expertise in industrial control electronics, we provide professional advice on PCB layout design, component selection, and electrical engineering, ensuring that the final design is optimized for manufacturability, cost - effectiveness, and performance.

One - Stop PCBA Service

Our commitment to clients doesn't end with the delivery of PCBA. We offer comprehensive after - sales support, including technical assistance, troubleshooting, and product maintenance. Our team of experts is available to respond to client inquiries promptly, helping to resolve any issues that may arise during the operation of industrial control systems. This after - sales support ensures the long - term reliability and performance of our PCBA solutions, providing clients with peace of mind.