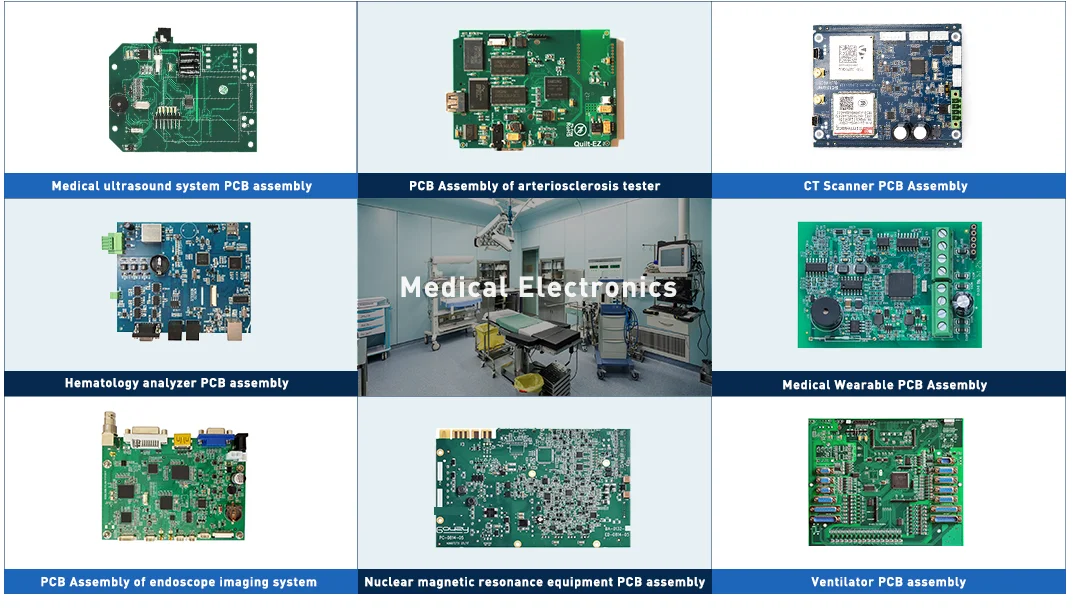

Medical Electronics

High-Reliability Medical PCBA Solutions by [KEEP BEST]

In the highly regulated and precision - driven medical industry, the reliability of Printed Circuit Board Assemblies (PCBA) can mean the difference between life and death. [KEEP BEST] is at the forefront of providing cutting - edge PCBA solutions tailored specifically for medical applications, leveraging our expansive manufacturing footprint and deep industry expertise.

Advantage :

As a premier medical PCBA service provider, we specialize in delivering reliable solutions for critical healthcare applications.

Ensure 100% compliance with ISO 13485 medical device standards

Implement 19-step quality control processes for zero-defect manufacturing

Support end-to-end PCBA solutions for medical imaging, patient monitoring, and life support devices

Advanced Manufacturing Capabilities

Spanning across two strategic locations in China and Thailand, our production bases cover a total area of 60,000 square meters, housing 16 high - performance SMT (Surface Mount Technology) production lines. This large - scale infrastructure forms the backbone of our ability to handle medical PCBA projects of all scales. These SMT lines are equipped with the latest high - speed pick - and - place machines, precision solder paste printers, and advanced reflow ovens. This setup enables us to achieve accurate component placement with tight tolerances, ensuring the consistent quality required for medical devices. Whether it’s for low - volume prototype runs or high - volume mass production, our SMT lines can be flexibly configured to meet your specific needs.

ISO 13485 - Certified Quality Assurance

Quality and compliance are non - negotiable in the medical field. As an ISO 13485 - certified company, our entire PCBA process, from component sourcing to final assembly and testing, adheres to the strictest international standards for medical device quality management. This certification validates our commitment to ensuring that every PCBA we produce is safe, reliable, and fully compliant with regulatory requirements.

Unparalleled Quality Control for Medical Standards

In the medical industry, where the slightest equipment malfunction can lead to catastrophic consequences, [KEEP BEST] adheres to uncompromising quality control protocols. To meet the sector's stringent requirements for ultra-low failure rates, pinpoint precision, and unwavering reliability, we've implemented an ISO 13485-certified Quality Management System (QMS).

Our manufacturing facility conducts comprehensive 100% inspections utilizing advanced Automated Optical Inspection (AOI) and X-Ray Fluoroscopy (XRF) technologies. AOI systems perform microscopic analysis of each Printed Circuit Board Assembly (PCBA), detecting minuscule soldering anomalies, component misalignments, and surface defects. Complementing this, XRF provides non-destructive, cross-sectional imaging of high-density assemblies, enabling the identification of latent issues such as solder bridging and Ball Grid Array (BGA) voids. Post-production, every unit undergoes Statistical Process Control (SPC) sampling inspections to ensure zero tolerance for defects. Our manufacturing process embodies engineering excellence through 19 meticulously defined Quality Assurance (QA) processes. From the procurement of Medical Device Single Audit Program (MDSAP)-compliant components to the final sterilization-ready packaging, each production phase is monitored by Industry 4.0-enabled sensors and overseen by our ASQ-certified quality engineers. In-line process controls include real-time solder paste inspection, automated component placement verification, and functional testing, ensuring immediate detection and resolution of any deviations from ISO 13845 standards. This holistic approach not only guarantees the precision and reliability of our medical PCBA solutions but also safeguards patient safety and maintains our clients' regulatory compliance.

Dedicated to Medical Applications

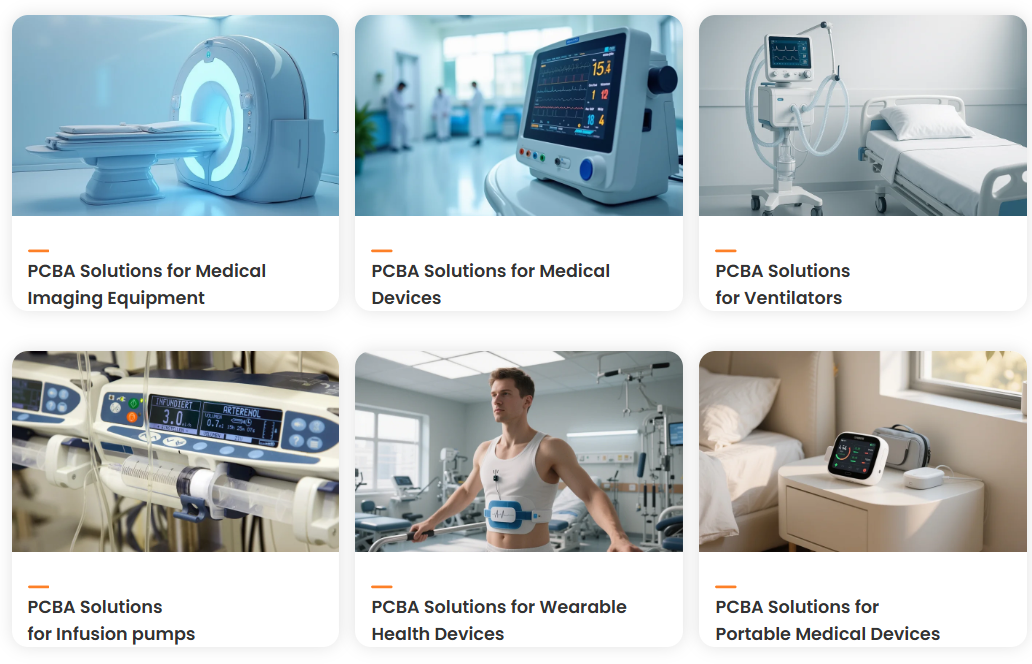

for Medical Imaging For complex medical imaging equipment such as MRI, CT scanners, and ultrasound devices, which demand high - speed signal processing and minimal electromagnetic interference, our PCBA solutions are engineered with meticulous attention to detail. Our experienced engineers optimize the layout and component selection to ensure accurate and stable operation, enabling precise diagnostic results.

Reliability for Patient Monitoring

Patient monitoring systems, including vital sign monitors, ECG machines, and intensive care unit equipment, require PCBA that can operate continuously and accurately. Our assemblies are designed to withstand 24/7 operation, providing reliable data collection and transmission to safeguard patient health.

Safety in Respiratory and Drug Delivery In life - supporting devices like ventilators, CPAP machines, infusion pumps, and syringe drivers, where precise control and safety are critical, our PCBA solutions play a vital role. We use high - quality, medical - grade components and implement strict quality control measures to ensure accurate dosage delivery and device functionality.

Comprehensive Service Offering

End - to - End Solutions [KEEP BEST] offers a one - stop service for all your medical PCBA needs. Simply provide us with your Bill of Materials (BOM) and PCB design files, and we’ll take care of the rest. Our services cover component sourcing, SMT assembly, quality control, functional testing, and final packaging. We have established partnerships with a global network of trusted component suppliers to ensure access to high - quality, medical - grade parts..

Rigorous Testing Regime

To guarantee the reliability of our medical PCBA, we conduct a series of comprehensive tests. Our quality control process includes Automated Optical Inspection (AOI) to detect soldering defects and component misplacement, X - Ray Inspection for hidden issues in high - density assemblies, and Functional Circuit Testing (FCT) to verify the overall functionality of the PCBA. These tests ensure that each product meets our stringent quality standards before it leaves our facility.

Technical Expertise and Support

Our team consists of over 450 skilled professionals, including experienced engineers, technicians, and quality control experts who specialize in medical PCBA. They are well - versed in the unique requirements of the medical industry and are available to provide technical support throughout the project lifecycle. From design optimization to troubleshooting, we work closely with you to ensure the success of your medical device project.

Why Choose [KEEP BEST]?

Proven Track Record: With years of experience serving the medical industry, we have a long list of successful projects and satisfied clients.

Fast Turnaround:

Our efficient production processes across our expansive 60,000 - square - meter production bases and 16 SMT lines allow us to offer competitive lead times, helping you bring your medical products to market faster.

Cost - Effective Solutions:

By leveraging our large - scale production and optimized supply chain across two major bases, we provide high - quality PCBA at competitive prices, helping you control costs without sacrificing quality.

Unrivaled Quality Assurance:

Our 100% inspection regime and 19 - step quality - control process ensure that our PCBA products meet the most exacting medical standards, giving you peace of mind and confidence in our products.

Partner with [KEEP BEST] for your medical PCBA needs and experience the difference of working with a trusted, reliable, and innovative partner. Contact us today to discuss your project and let us help you bring your life - changing medical devices to reality.