Vehicle electronics

High-Reliability Automotive Vehicle Electronics PCBA Solutions by [KEEP BEST]

In the rapidly evolving landscape of automotive technology, where safety, reliability, and performance are non-negotiable, [KEEP BEST] stands as a trusted partner for advanced Printed Circuit Board Assembly (PCBA) solutions tailored to automotive applications. Our expertise in delivering high-reliability PCBA for vehicle electronics is rooted in decades of industry experience, state-of-the-art manufacturing capabilities, and unwavering commitment to quality.

ISO 16949-Certified Excellence

Rigorous Automotive-Grade Testing 100% inspection: AOI, X-Ray, FCT.

Global Manufacturing with Specialized Capabilities 60,000㎡ bases in China/Thailand with 16 SMT lines (dedicated for automotive).

Holding ISO 16949:2016, [KEEP BEST] ensures full-process traceability and risk management, meeting automotive OEMs’ strict reliability demands for harsh environments.

Advanced Manufacturing Capabilities

Strategic Production Footprint With two world-class production bases in China and Thailand, spanning a total area of 60,000 square meters, [KEEP BEST] boasts a robust manufacturing infrastructure. Our facilities are equipped with 16 high-performance SMT (Surface Mount Technology) production lines, including dedicated lines for automotive PCBA, ensuring we can handle projects of any scale with precision and efficiency.

Automotive-Grade Equipment

Our SMT lines are outfitted with cutting-edge technology, including high-speed pick-and-place machines, precision solder paste printers, and advanced reflow ovens. This enables us to achieve tight tolerances, precise component placement, and consistent quality, essential for automotive electronics that must withstand vibration, temperature fluctuations, and electrical interference.

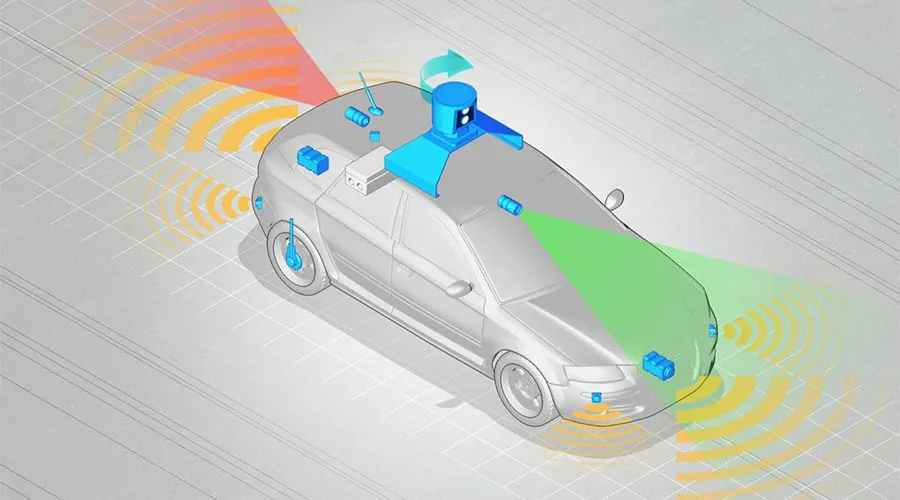

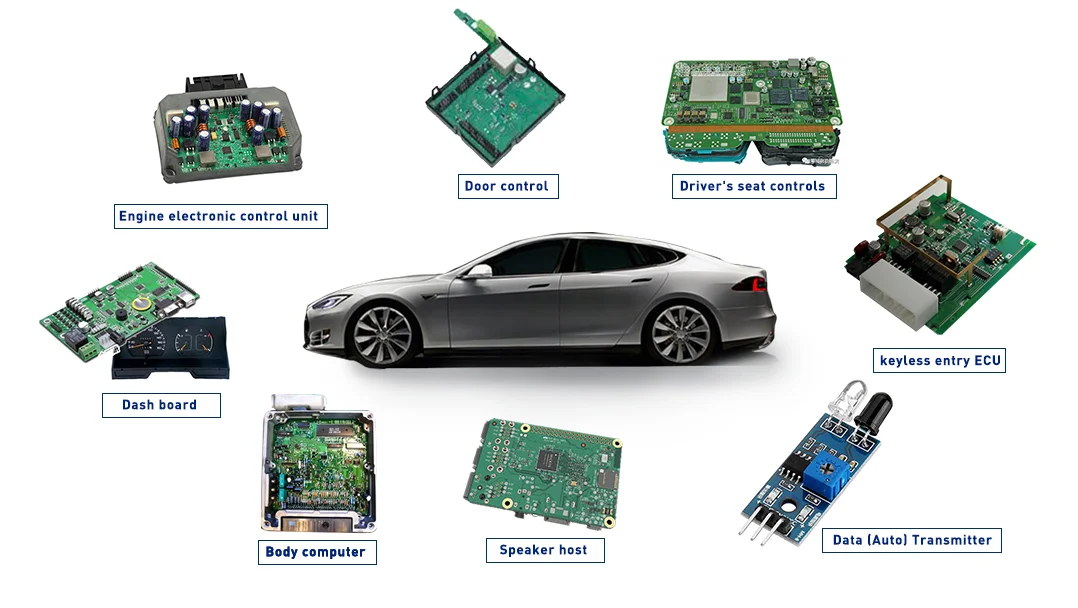

Specialized Solutions for Automotive Applications

Driver Assistance Systems (ADAS) [KEEP BEST] provides PCBA solutions for ADAS components, including radar modules, camera systems, and LiDAR controllers. Our assemblies are designed to meet the high-speed processing and low-latency requirements of ADAS, ensuring real-time data processing for safer driving.

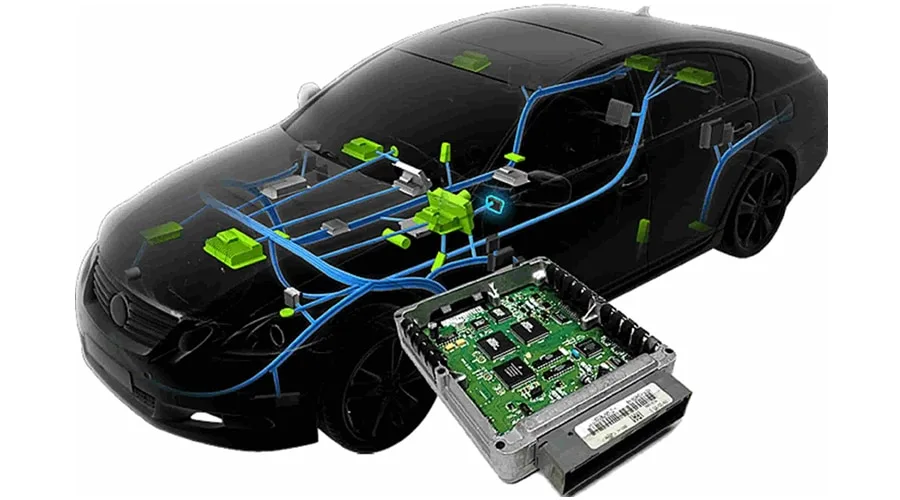

Engine Control Units (ECU)

We specialize in PCBA for ECUs, which are the brain of modern vehicle engines. Our solutions are engineered to withstand high temperatures, electromagnetic interference, and mechanical stress, ensuring reliable engine management and optimal performance.

Infotainment and Connectivity Systems

For in-vehicle infotainment (IVI) systems, telematics units, and connectivity modules, we deliver PCBA that combine high-performance computing with robust connectivity. Our assemblies support the latest communication protocols and ensure seamless user experiences.

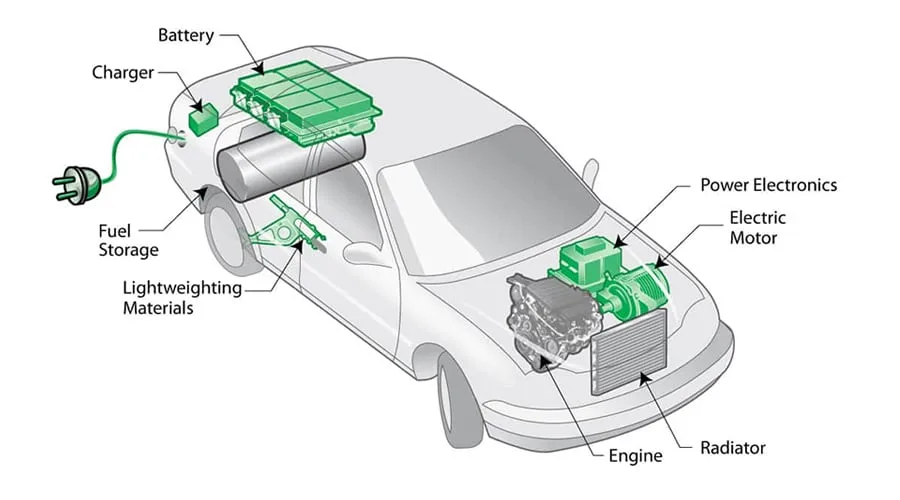

Battery Management Systems (BMS)

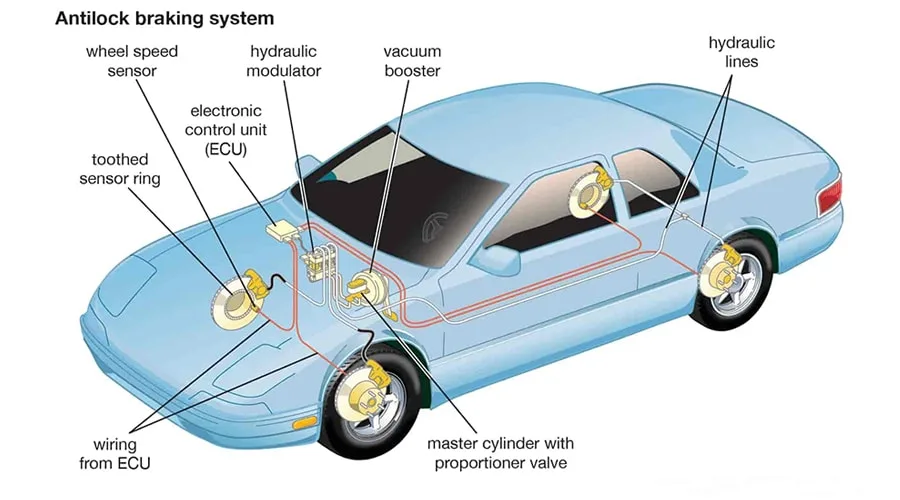

[KEEP BEST] offers PCBA solutions for BMS, critical for electric vehicles (EVs) and hybrid vehicles. Our assemblies enable precise battery monitoring, charge management, and safety control, contributing to improved battery life and vehicle range.Safety Systems

From airbag control units to anti-lock braking systems (ABS) and electronic stability control (ESC), our PCBA solutions are designed to meet the highest safety standards. We implement redundant designs and rigorous testing to ensure fail-safe operation in critical safety applications.

Stringent Quality Control for Automotive Reliability

100% Inspection Regime

Understanding the critical nature of automotive electronics, we implement a comprehensive 100% inspection process. This includes:

Automated Optical Inspection (AOI) for surface defects and soldering anomalies

X-Ray Inspection for hidden issues in high-density assemblies and BGA components

Functional Circuit Testing (FCT) to verify overall functionality.

19-Step Quality Control Process

Our manufacturing process incorporates 19 meticulously defined quality control steps, from component sourcing to final packaging. Each step is monitored to ensure compliance with automotive standards, including:

Incoming material inspection for automotive-grade components Solder paste inspection and verification Real-time process monitoring during assembly Environmental stress testing, including temperature cycling and vibration testing Final functional testing and validation

Automotive-Grade Testing

To simulate the harsh automotive environment, we conduct specialized tests such as:

Incoming material inspection for automotive-grade componentsTemperature cycling (-40°C to +125°C) to verify performance in extreme temperatures

Vibration testing to ensure durability in dynamic conditions

Humidity and corrosion resistance testing.

Electromagnetic compatibility (EMC) testing to minimize interference

Comprehensive Service Offering

End-to-End Solutions

[KEEP BEST] offers full turnkey PCBA services for automotive electronics, including:

Component sourcing from approved automotive suppliers

PCB design and optimization for automotive applications

Testing and validation

Final assembly and packaging

Design for Manufacturing (DFM)

Our engineering team provides DFM analysis to optimize your design for automotive manufacturing, ensuring reliability, cost-effectiveness, and manufacturability. We consider factors such as thermal management, signal integrity, and mechanical robustness.

Supply Chain Management

With the ISO 16949-certified supply chain management system, we ensure traceability and reliability of components. Our team of over 50 sourcing engineers partners with automotive-approved suppliers to secure high-quality components, even for long-life cycle automotive projects.

Why Choose [KEEP BEST] for Automotive PCBA?

ISO 16949 Certified: Our quality management system meets the strict automotive industry standards.

Dedicated Automotive Expertise: Years of experience in delivering PCBA for various automotive applications.

Advanced Facilities: 60,000 sq.m production bases with 16 SMT lines, including dedicated automotive lines.

Rigorous Testing: 100% inspection and specialized automotive testing to ensure reliability.

Scalability: Capability to handle low-volume prototypes and high-volume mass production.

Global Presence: Production bases in China and Thailand for strategic location and efficient logistics.