Design Services

Your Premier Partner for Full-Cycle PCB Design

In the rapidly evolving landscape of electronics, Printed Circuit Boards (PCBs) serve as the backbone of countless devices, powering everything from consumer electronics to cutting-edge industrial applications. At [ KEEP BEST], we pride ourselves on being at the forefront of PCB design, offering comprehensive solutions that span the entire lifecycle of your project. Our commitment to excellence, technical expertise, and customer satisfaction sets us apart as the go-to partner for all your PCB design needs.

Full-Cycle PCB Design Expertise

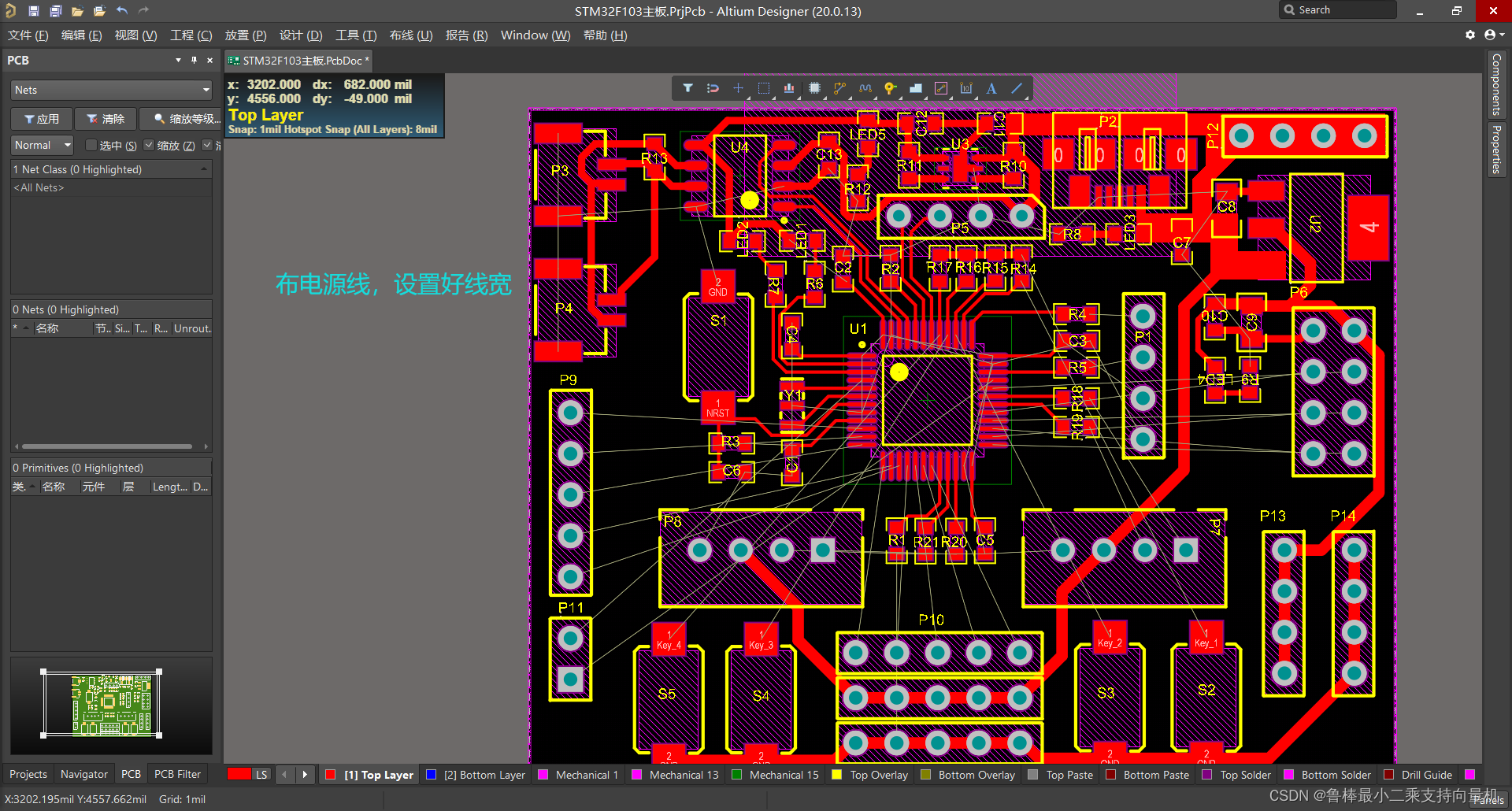

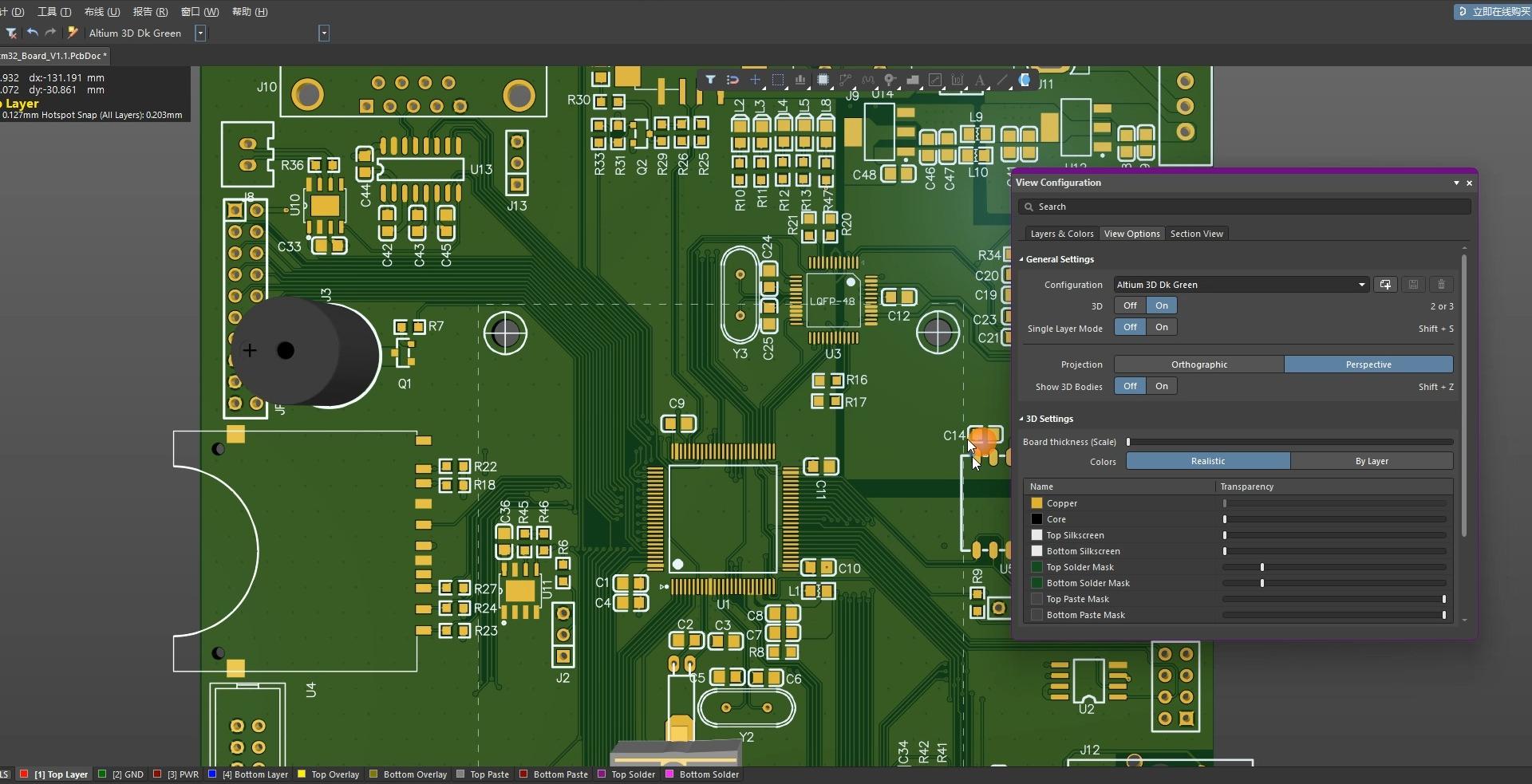

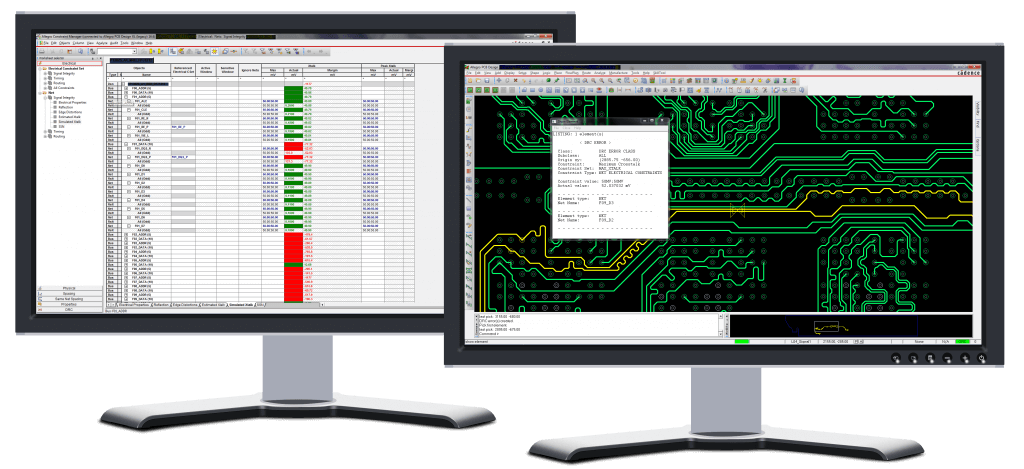

Our team of highly skilled and experienced PCB designers possesses a deep understanding of the intricacies involved in creating high-performance, reliable, and cost-effective PCBs. We leverage the latest design tools and technologies to ensure that every aspect of your PCB is optimized for functionality, manufacturability, and scalability. From concept development and schematic capture to layout design, routing, and verification, we handle every step of the design process with meticulous attention to detail.

Concept Development: We work closely with you to understand your project requirements, performance goals, and budget constraints. Our designers use this information to develop a comprehensive design concept that meets your needs and exceeds your expectations.

Schematic Capture: Our schematic capture experts use industry-standard tools to create accurate and detailed schematics that serve as the foundation for your PCB design. We ensure that all components are properly selected, placed, and connected to meet your design specifications.

Layout Design: Our layout designers use advanced design techniques and tools to create efficient and optimized PCB layouts that minimize signal interference, power consumption, and electromagnetic compatibility (EMC) issues. We pay close attention to component placement, routing, and layer stackup to ensure that your PCB meets the highest standards of performance and reliability.

Routing: Our routing experts use automated routing tools and manual routing techniques to create high-quality, error-free PCB routes that meet your design specifications. We ensure that all traces are properly routed, spaced, and terminated to minimize signal loss and interference. Verification: Our verification engineers use a combination of automated and manual testing techniques to ensure that your PCB design meets all design specifications and requirements. We perform comprehensive electrical, mechanical, and thermal simulations to identify and resolve any potential issues before production.

Prototype-to-Mass Production Support

We understand that the transition from prototype to mass production can be a challenging and complex process. That's why we offer comprehensive support services to help you navigate this critical phase of your project. Our team of experts works closely with you to ensure that your PCB design is optimized for mass production, and we provide ongoing support throughout the production process to ensure that your project is completed on time, within budget, and to the highest standards of quality.

Design for Manufacturability (DFM): Our DFM experts review your PCB design to identify any potential manufacturability issues and recommend design modifications to improve production efficiency and reduce costs. We ensure that your PCB design is optimized for the manufacturing process, including component placement, routing, and layer stackup.

Prototype Development: We offer fast and reliable prototype development services to help you quickly validate your PCB design and test its functionality. Our prototype development process includes schematic capture, layout design, routing, verification, and fabrication. We use the latest prototyping technologies and techniques to ensure that your prototypes are of the highest quality and meet your design specifications.

Mass Production: Our mass production services are designed to meet the highest standards of quality, reliability, and efficiency. We work with a network of trusted manufacturing partners to ensure that your PCBs are manufactured to your exact specifications and delivered on time, every time. Our mass production process includes component sourcing, assembly, testing, and quality control.

Supply Chain Management:We offer comprehensive supply chain management services to help you manage the procurement, inventory, and logistics of your PCB components and materials. Our supply chain management team works closely with you to ensure that your components and materials are sourced from reliable suppliers at the best possible prices, and we manage the inventory and logistics of your components and materials to ensure that they are available when you need them.

Post-Production Technical Support

Our commitment to customer satisfaction doesn't end with the delivery of your PCBs. We offer comprehensive post-production technical support services to help you ensure the long-term reliability and performance of your products. Our team of experts is available to answer your questions, provide technical assistance, and resolve any issues that may arise after production.

Technical Support: Our technical support team is available to answer your questions, provide technical assistance, and resolve any issues that may arise after production. We offer a variety of support channels, including phone, email, and online chat, to ensure that you can get the help you need, when you need it.

Product Warranty: We offer a comprehensive product warranty to ensure the long-term reliability and performance of your products. Our warranty covers defects in materials and workmanship, and we will repair or replace any defective products at no charge.

Product Upgrades and Enhancements: We offer product upgrades and enhancements to help you improve the performance, functionality, and reliability of your products. Our product upgrade and enhancement services include software updates, hardware upgrades, and design modifications.

Reverse Engineering: Our reverse engineering services are designed to help you analyze and understand the design and functionality of existing PCBs. We use advanced reverse engineering tools and techniques to create accurate schematics, layouts, and bill of materials (BOMs) for existing PCBs, which can be used for design modification, product improvement, or intellectual property (IP) protection.

Why Choose Us?

Technical Support:Our team of highly skilled and experienced PCB designers, engineers, and technicians possesses a deep understanding of the latest design tools, technologies, and techniques. We stay up-to-date with the latest industry trends and advancements to ensure that our solutions are always at the forefront of innovation.

Quality Assurance: We are committed to delivering the highest quality PCB design solutions that meet or exceed your expectations. Our quality assurance process includes comprehensive electrical, mechanical, and thermal simulations, as well as rigorous testing and inspection at every stage of the design and production process.

Customer Satisfaction: We believe that customer satisfaction is the key to our success. That's why we work closely with you to understand your needs and requirements, and we provide ongoing support and communication throughout the entire project lifecycle. Our goal is to ensure that you are completely satisfied with our services and the final product.

Competitive Pricing: We offer competitive pricing without compromising on quality or service. Our pricing model is transparent and flexible, and we work with you to develop a pricing plan that meets your budget and requirements.

Fast Turnaround Times: We understand that time is of the essence in the electronics industry. That's why we offer fast turnaround times without sacrificing quality or accuracy. Our team of experts works efficiently to ensure that your project is completed on time, every time.

Contact Us Today

If you're looking for a reliable and experienced partner for your PCB design needs, look no further than [ KEEP BEST]. Contact us today to learn more about our services and how we can help you bring your next project to life. Our team of experts is ready to answer your questions, provide a quote, and discuss your project requirements. Let us show you why we're the premier choice for PCB design.

Is there a minimum order quantity (MOQ) for product orders?

No, we adopt a flexible order mechanism, there is no MOQ for products; The number of orders is entirely up to you.Thank you for choosing KeepBest.

What is your testing policy and how you control the quality?

ln order to guarantee PCB product quality,usually tested by flying probe; electrical fixture; automated optical inspection (AOI); X-ray inspection for BGA parts; first article inspection (FAl), and so on.

What service do you have?

We can offer OEM service including PCBA making, PCB assembly, components sourcing. Additionally, we can also provide programming, testing, cables, enclosure assembly service.

Do you support quick proofing?

Yes,we support 3-7 days fast proofing.

Are my files safe?

Your files are held in complete safety and security. We protect the intellectual property for our customers in the whole process. All documents from customers are never shared with any third parties. NDA can be signed.

If we have order production needs, how can we contact you?

Thank you very much for your trust in our company. If you have any questions, please feel free to email our sales team at mailto:market@keepbestpcba.com. We are available 24/7 to serve you.