Location

7/47 Moo 4 Phana Nikhom, Nikhom Phatthana District,Rayong 21180

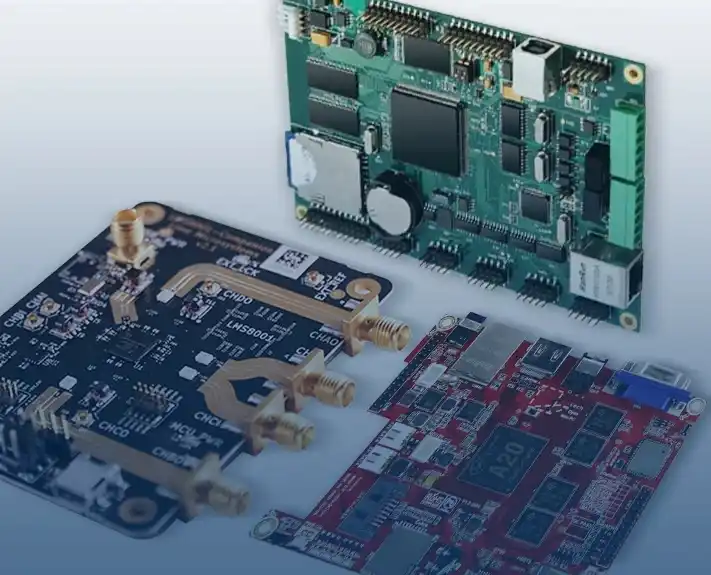

Full-Cycle PCB Design Expertise

Prototype-to-Mass Production Support

Post-Production Technical Support

Integrated Cost-Efficiency Design.

Automation-Optimized Assembly

Reliability-Driven Manufacturing.

Fast Turnkey PCB Solutions

Prototype-Driven Design Perfection

Flexible Volume Manufacturing

Ultra-Fast Delivery Assurance

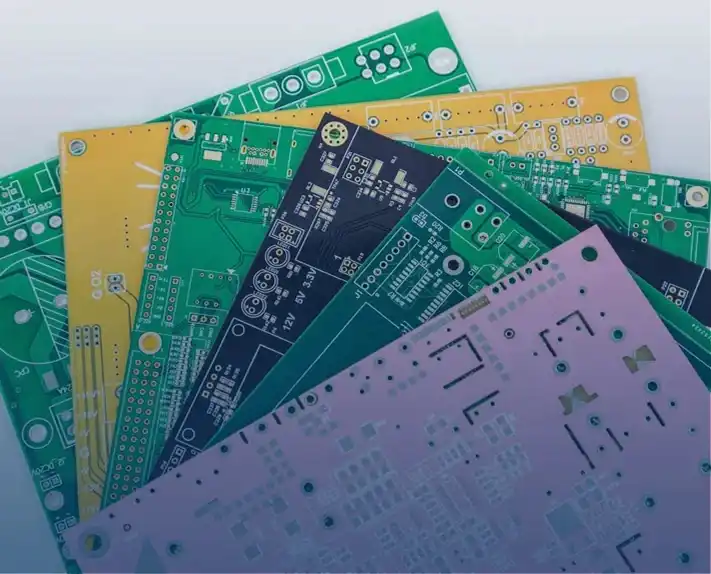

Flexible Turnkey Assembly Options

Scalable Craftsmanship Expertise

Cost-Efficient Rapid Sourcing

Reliable Authorized Supply Chains

Customized Procurement Flexibility

Comprehensive Defect Detection

Engineer-Certified Protocols

End-Stage Quality Assurance

RFQ (Request for Quotation).

Technical Review

BOM (Bill of Materials).

Review Cost Estimation

PO (Purchase Order) Confirmation. Contract Signing. Payment Terms. Lead Time Agreement

Gerber File Review Component Sourcing PCB Fabrication Surface Mount Technology

SMT Assembly. DIP (Dual In-line Package) Insertion. Automated Optical Inspection. Functional Testing

Final Inspection. Packaging. Logistics Arrangement. Shipment

Please upload your Gerber files and BOM. You can upload an unlimited number of files as long as the total size of all files does not exceed 20 MB. To ensure you receive your official quote in less than 24 hours, please include the quantity of circuit boards for which you would like a quote. please send it to us prior to sending your files and we will be happy to accommodate.

7/47 Moo 4 Phana Nikhom, Nikhom Phatthana District,Rayong 21180

Wednesday - Sunday

7:00 AM - 5:00 PM

Address: 7/47, Moo 4, PhanaNikhom Sub-district, NikhomPhatthana District, Rayong 21180, Thailand

Wednesday - Sunday

7:00 AM - 5:00 PM