R&D Assistance

Research & Development

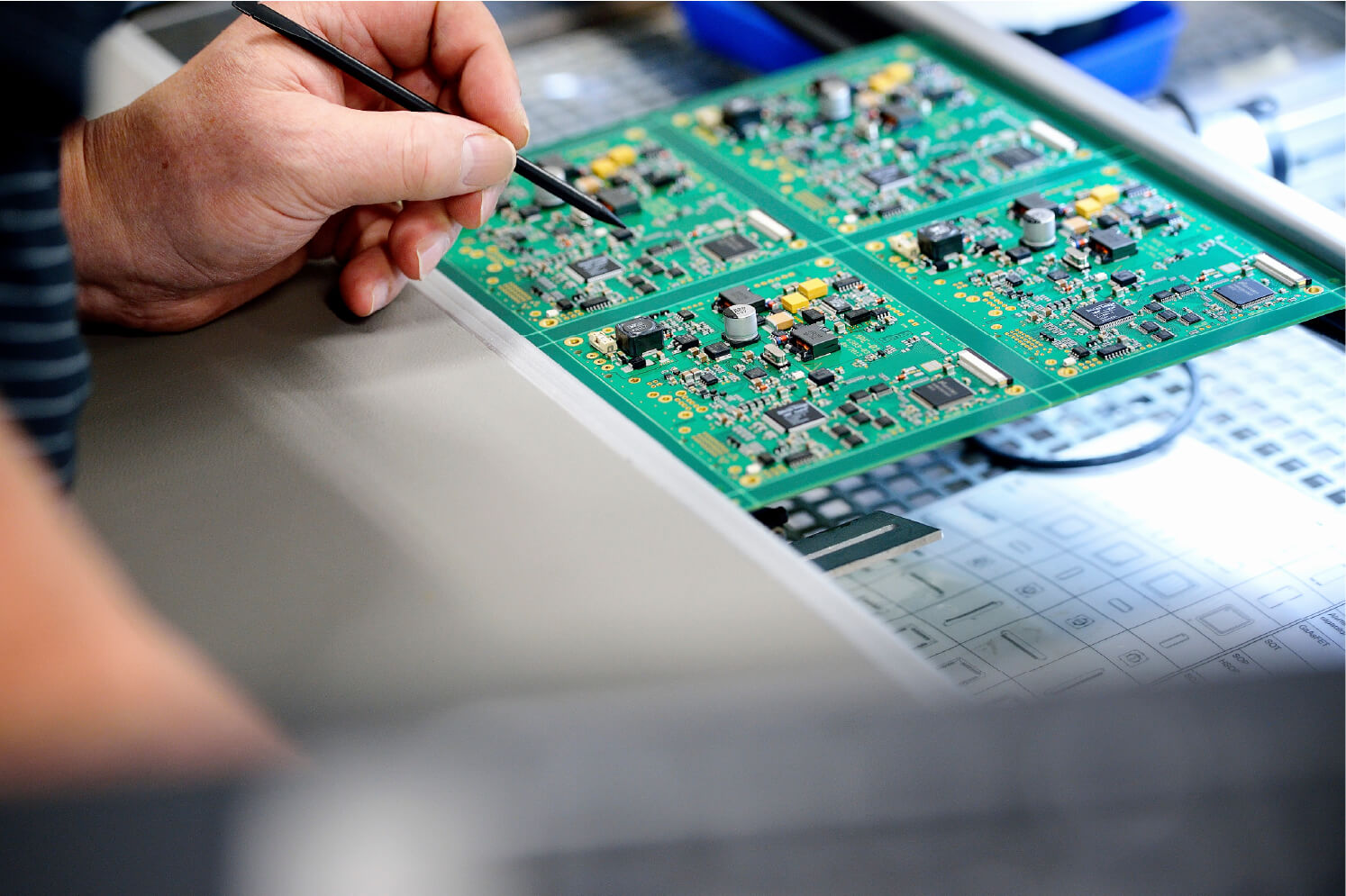

PCB Hardware Design Support

- Solution Selection & Feasibility Analysis

- High-Density Layout & Routing Guidance

- Hardware-Software Co-Debugging

- Hardware Interface Compatibility Optimization

- Design for Manufacturability (DFM) Validation

Embedded Software Development

- Driver Layer Development Support

- Test Verification System Construction

- Modular Design Reuse Technology

Intelligent Terminal Development

- Android/iOS Native APP Development

- Program Customization

- IoT Device Cloud Integration

- Human-Machine Interface (HMI) Design

PCB Reverse Engineering Services

- Component Reverse Analysis

- Schematic Reverse Restoration

- Intellectual Property Compliance Assurance

- Multi-Layer Board Precision Cloning

- Design Defect Repair & Upgrade

- Chip Decryption & System Reconstruction

Advantages in Service

We produce, you benefit.

Whether you need prototypes, series in different batches/sizes or services at short notice –kbpcba is your professional EMS service provider with a complete portfolio of assembly options.

State-of-the-art equipment and a team of experienced engineers and skilled workers ensure a high standard of manufacturing for your products. Naturally, assemblies are manufactured exclusively in an air-conditioned and ESD-compliant environment. Our extensive software and hardware test facilities ensure the highest quality. We also have the capability for automated test setups in accordance with your individual requirements.

SMD/ SMT assembly

SMD/ SMT assembly

If you don’t know how to do the work, you can’t offer anything special: kbpcba offers it’s customers the best possible quality in SMD assembly.

Thanks to modern production technology and a multi-stage manufacturing and testing process, kbpcba is able to produce not only demanding small and medium series, but also large series with maximum functional reliability. On request, prototypes can also be assembled in series production to eliminate any quality difference between prototype and series versions.

Enclosures that, by their nature, cannot be fully assembled by machine are assembled by hand. Specially adapted soldering processes protect sensitive components and PCBs. All assembled PCBs are visually inspected after soldering to confirm and complete the SMD assembly process.

kbpcba guarantees the best possible delivery times and, thanks to its flexible processes, can also help at short notice.

Our capacity is not a challenge, we have the flexibility to adapt.

kbpcba – Your partner with competitive prices and the highest level of quality.

THR assembly

Are you looking for particularly mechanically stable through-hole solder connections combined with the efficient automated production processes of surface mounting? kbpcba has been using this technology for over 20 years.

THR assembly takes place in the SMD process. Unlike manual THT placement, in the THR process the wired components are automatically placed by the SMT machines.

On request, our specialists can help you with your specific requirements: both the components and the design of the printed circuit boards are subject to specific criteria.

THT assembly

kbpcba has been your reliable partner for manual THT assembly.

High concentration, conscientious execution, special care, a great deal of routine – specially trained personnel carry out the work with a wealth of experience. They are optimally supported by detailed work instructions and production documentation, and by a process that allows any deviations detected to be corrected immediately and permanently. The soldering process is mechanical, with manual soldering used where this is not technically possible.

processes all common designs for you, from small to large series.

Development Skills at a Glance

- Software development (firmware and applications)

- Hardware development, from subtasks to complete systems on demand

- Development of electronic circuits and components

- Design of PCB (circuit diagrams, assembly plans, layout)

- Design including approvability of mounting and connecting elementsDevelopment of complete devices and systems including component and material selection

- Redesign and re-engineering

- Optimisation of existing equipment and systems

- Design with CE, UL, CCC, EAC verificationDevelopment of test and inspection equipment, not only for R&D components but also for third party components

- Development of production equipment and auxiliariesProduction optimisation of assemblies and devicesCAD data for further development, production of assemblies or even end-to-end production

Of course, we work in accordance with standard project management systems with requirement specifications, functional specifications, feasibility studies, samples, rapid prototypes and proofs of concept.

Design und Layout

Do you need support with new developments or the revision or optimisation of existing projects? kbpcba will take you from the idea to the finished product!

Our design approach is focused on the production and test environment. Early adaptation of the layout to the manufacturing process results in high process reliability and product quality. Benefit from synergy effects and cost savings by optimising production steps and selecting components and materials. In consultation with our customers, PCB manufacturers and our production specialists, we create specific PCB benefits during the design phase, with particular emphasis on quality and manufacturing feasibility under economic conditions.

Hardware and Software Development

At kbpcba you will find a comprehensive portfolio of development services that is not limited to the development of electronics and software, but also includes mechanics. If required, we can also bring in external partners for industrial design.

We work in partnership with our customers from the earliest stages of development. This enables us to provide high-quality, cost-optimised products that meet the needs of the market.

We provide support in areas such as conception, component selection, circuit development and test design. Mechanical and enclosure design is also part of our service.

Key elements of kbpcba hardware development: Design to Cost, Design for Manufacturing and Design for Testability.

At kbpcba, we start at the routing stage to create the basis for assemblies that can be efficiently manufactured and tested. We develop circuit concepts and schematics, select suitable components and create PCB layouts. We consider all relevant specifications, including EMC and safety. The production process is carried out in constant consultation with our engineers and technicians in the development department. Samples and prototypes of your module, device or system are then built for functional testing or adaptation for further development.

Assistance with Assemblies, Devices and Systems

Manufacturing is our core competency. We are experts in component selection.

This applies to kbpcba not only for assemblies, but also for complete devices and systems.

Our design engineers can optimise or modernise your components and products to meet your requirements, drawing on our extensive expertise.

Working closely with your contact personnel, we redesign components not only for updates, but also for modern functionality. Not always common in the market, but standard for us: after completion, you will receive all development documents.

Concept for Testing

Testing is an important part of any manufacturing process.

We always tailor the test procedure to your product or requirements. During the product development phase, a concept can be developed with you or to your specifications. This will ensure that the required quality targets are met. This will result in a finished test equipment.

We provide this service not only for components manufactured by us, we also provide it for components manufactured by third parties.

At kbpcba, you can rely on a variety of test methods throughout the production process, which can be combined according to your requirements. Take advantage of our expertise to combine the benefits of different test methods to achieve the highest possible process reliability.

An optimal testing strategy includes considering the following points:

-

Laws, regulations, standards, etc.

-

Required quality

-

Product design (design for test)

-

Previous experience and test results

-

Quantity and batch size

-

and much more.