PCBA Manufacturing in Thailand: How KeepBest Delivers Reliable Circuit Board Solutions

PCBA Manufacturing in Thailand: How KeepBest Delivers Reliable Circuit Board Sol

PCBA Manufacturing in Thailand: How KeepBest Delivers Reliable Circuit Board Solutions

Thailand has emerged as a global hub for high-precision electronics manufacturing, and at the forefront of this growth is KeepBest PCBA—a one-stop PCB assembly (PCBA) provider redefining reliability and efficiency in the industry. With over 13 years of expertise, KeepBest combines Thai manufacturing excellence with global standards, offering end-to-end solutions from prototype to mass production.

Why Thailand? The KeepBest Advantage

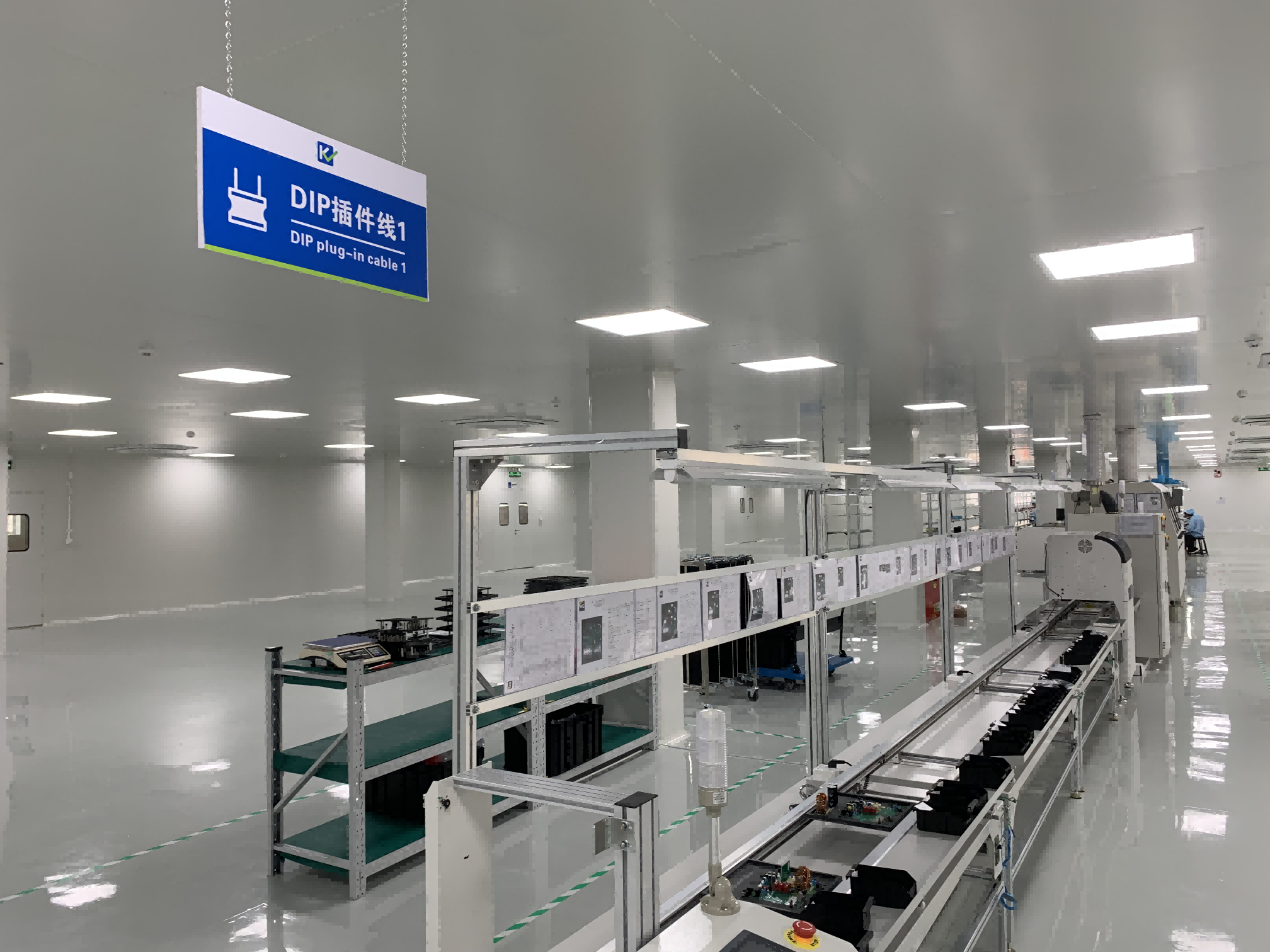

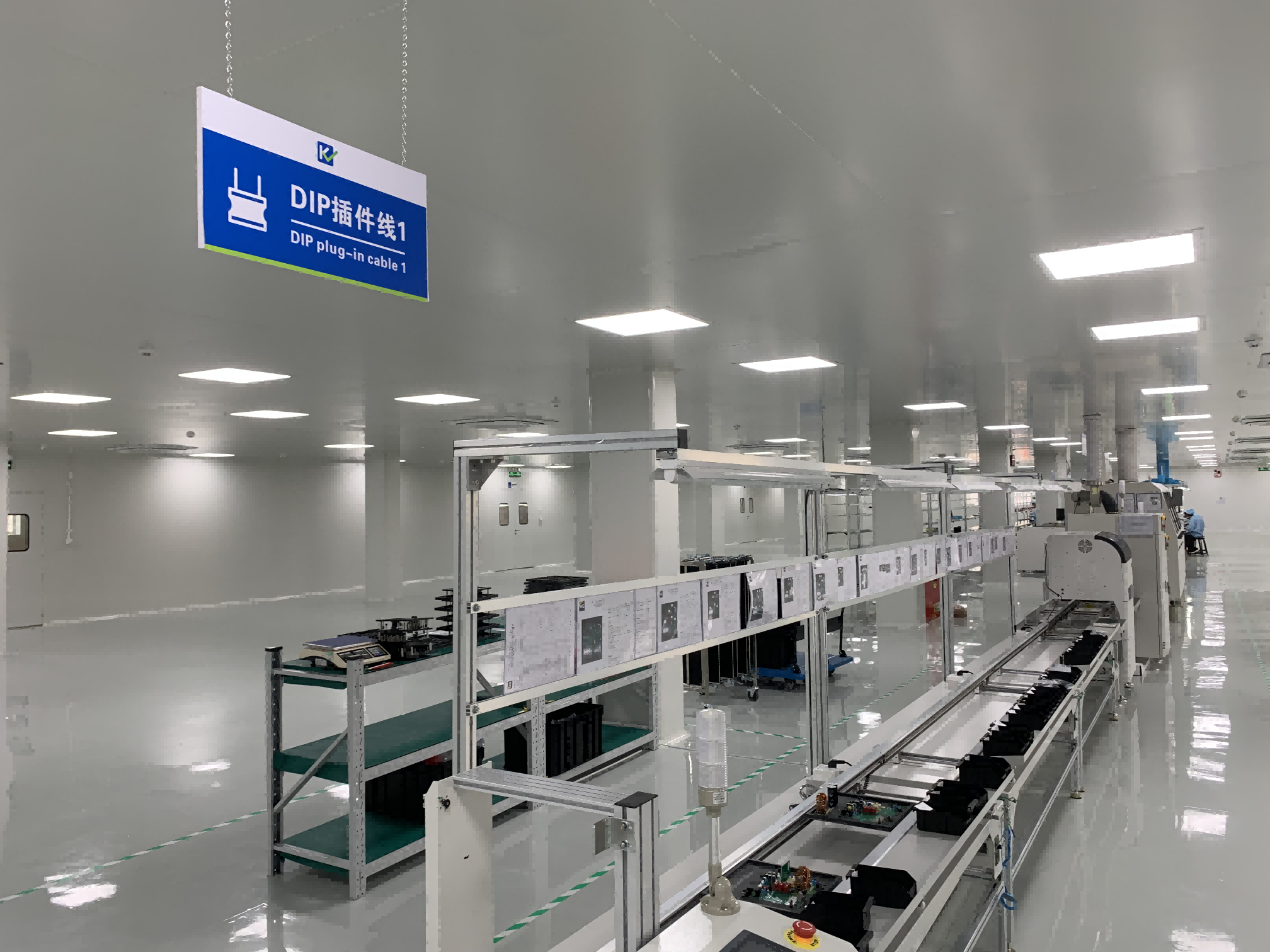

Nestled in Rayong, Thailand, KeepBest’s state-of-the-art facility is a cornerstone of its global operations, complemented by production bases in Shenzhen and Jiangmen, China. Spanning over 60,000 square meters, the Thai plant houses 14 SMT lines, clean-room assembly zones, and advanced inspection technologies—including 100% AOI (Automated Optical Inspection) and X-ray systems—ensuring precision even for the most complex projects.

Certified to ISO 13485 (medical) and IATF 16949 (automotive), KeepBest meets the stringent demands of regulated industries. Its technical prowess shines in high-precision manufacturing: handling line widths as narrow as 50μm, micro-pitch soldering down to 0.25mm, and complex processes like mixed assembly, underfill, and 20+ layer PCBs. This capability makes it a trusted partner for medical devices, automotive electronics, industrial control systems, and IoT applications.

One-Stop Solutions: From Design to Delivery

KeepBest’s “turnkey EMS” model streamlines the entire production cycle, eliminating bottlenecks for clients worldwide. Services include:

- End-to-end engineering: PCB layout, product design, and DFM/DFA optimization to enhance manufacturability.

- Component sourcing: Leveraging partnerships with authorized suppliers (e.g., Digi-Key, Mouser) and a database of 600+ long-lead components to ensure supply chain resilience.

- Rapid production: Prototypes in as little as 5 days, small batches in 20 days, and emergency builds within 72 hours—critical for time-sensitive projects.

- Global delivery: Duty-ready shipments to 100+ countries, with duty optimization to reduce client costs.

Quality That Speaks for Itself

Reliability is non-negotiable at KeepBest. Its quality control includes:

- Advanced testing: ≥95% coverage via ICT/FCT, plus ORT (Operational Reliability Test) reports for long-term performance validation.

- Full traceability: MES (Manufacturing Execution System) and 8D reports track every component and process step.

- Zero-defect commitment: Backed by rigorous protocols and engineer-certified inspections, ensuring compliance with medical and automotive grade standards.

Trusted by Global Leaders

From medical device manufacturers to automotive giants, KeepBest partners with brands like Huawei, Siemens, and Tesla—proof of its ability to scale with diverse needs. Whether a startup needing prototypes or an enterprise requiring mass production, KeepBest adapts with flexible order sizes (no minimums) and cost-efficient solutions tailored to each client.

In Thailand’s competitive PCBA landscape, KeepBest stands out as a blend of technical precision, global reach, and uncompromising quality. For businesses seeking a reliable partner to turn ideas into market-ready electronics, KeepBest delivers—from design to delivery.

Keywords: PCBA manufacturing Thailand, KeepBest PCBA, one-stop PCBA solutions, medical grade PCBA, automotive PCBA, SMT assembly Thailand

Leave a Reply

Your email address will not be published. Required fields are marked *